Coalition in 3D for Soft Materials

– Headed By Prof. Dr. Riza Sulaiman.

Handling collision detection when cloth undergone wrinkles still requires full attention and improvement on how to reduce highly intensive computation and maintaining the cloth wrinkles realistically and stable. An efficient self-collision technique which can improve self-collision handling that is able to avoid penetration of cloth nodes are considered as the main goal that needs to be achieved in simulating virtual cloth in computer graphics.

INTRODUCTION OF RESEARCH

The ability to simulate cloth with crumpled effects using 3D cloth simulation is important in computer graphics. Some evidence on the implementation of cloth model simulation proved that the element of complex collisions requires high computation time. To reduce this computation time, earlier researchers used simple mathematical formulae and a computational technique known as Mass-Spring System Network (MSN) in modeling cloth.

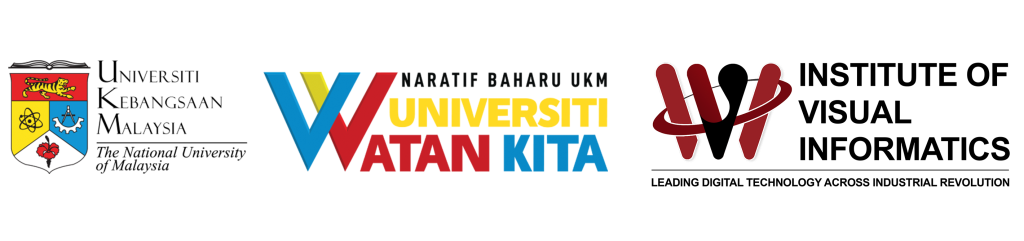

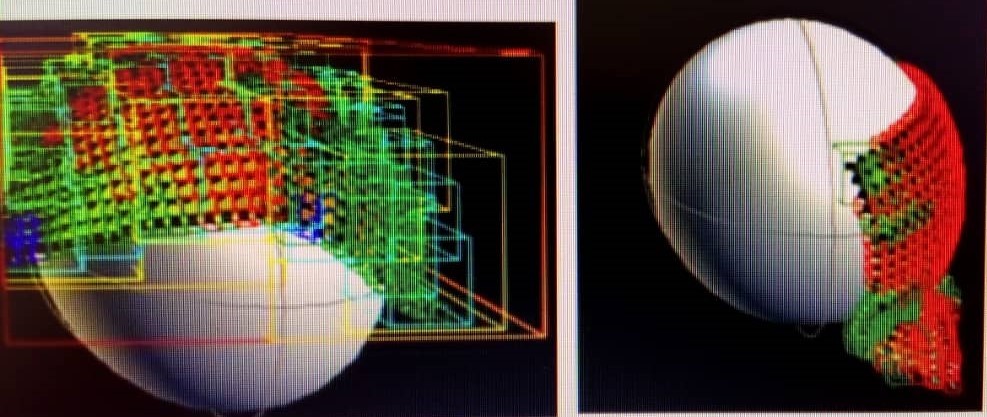

Nevertheless, this simulation process requires high computation time while at the same time increasing the computation process of Collision Response (CR) between the surfaces of the cloth to stabilise the collisions that have occurred. Thus, The Institute of Visual Informatic (IVI), UKM has developed an efficient SCD technique by integrating two techniques known as the nBlock Oct-Tree (nBOct-Tree) and Velocity Correction Position-Based Dynamic (VcCPBD). This technique was introduced to improve the balancing technique of Bounding Volume Hierarchies (BVH). By using nBOct-Tree technique in cloth simulation, BVH processing time is 11.524 milli seconds faster than existing technique. Meanwhile, the VcCPBD technique has been developed and integrated with the nBOct-Tree technique to enhance the stability of collision response involving the elements of the position, velocity and acceleration of nodes particles after SCD collision. Our results showed that the collisions recorded for the VcCPBD technique is not more than 5 milli seconds at each time step. Now, computer experts will have no problem in simulating soft materials in 3D again.

FINDINGS OF RESEARCH

It was also found that the average collision recorded for the developed integration techniques is 1.018% less than in the existing technique while at the same time stabilising the collision between the nodes particles of the cloth to prevent the penetration on the crumpled cloth surfaces.

FUTURE WORKS

This technique helps in reducing the problem of handling computation self-collision detection once cloth surfaces undergone wrinkle and twist process. For the use in our cloth simulation system, we showed that clustering is the best choice which does not state the minimum number of particles that must exist in the cluster region. The collision checking procedure between cloths surfaces can only be performed once a surface point contained by the predefined spherical clusters. The implementation of this technique is successfully done in cloth simulation. Future work shall be done for soft materials with different density.